We own the license for SOLID WORKS and SOLID CAM

For information you can call us at 0908 034 491 or 0911 289 424

CNC MILLING

metal parts and components

We use professional CNC technology to manufacture metal and plastic parts, even in the case of complex shapes or piece production.

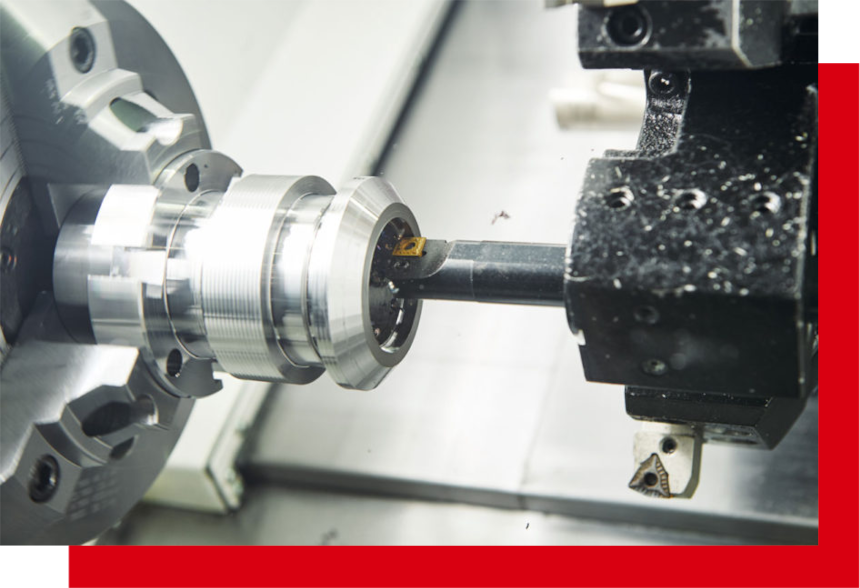

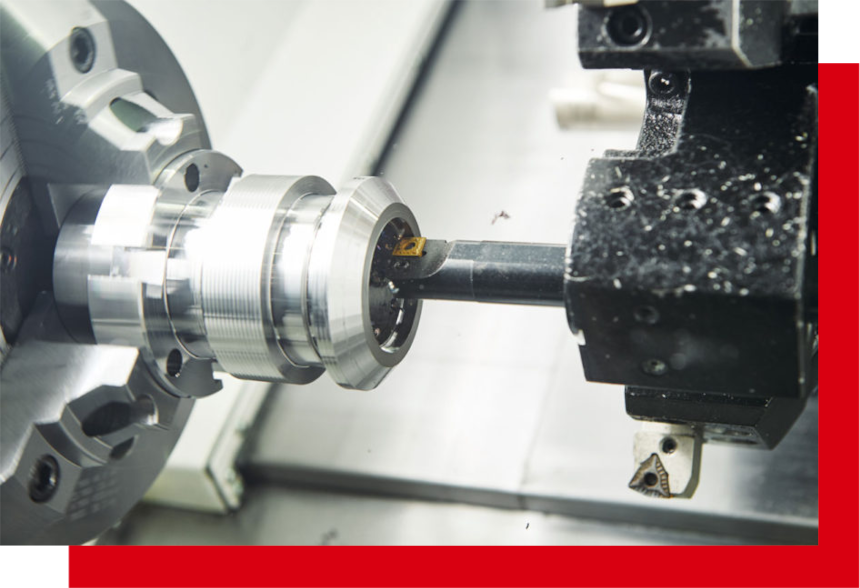

CNC TRIMMING

metal and stainless steel parts

We cover the production of rotating parts made of steel, stainless steel, duralumin, plastic or other materials, even in the case of small batch production. We are able to offer CNC turning services to clients in a variety of industries, most often working with the automotive, food and electrical industries. We also turn difficult shapes, more complicated parts and provide final machining of the metal part.

PROJECT SOLUTIONS

for engineering parts, components, workpieces

We provide reverse engineering and we create a production plan and design solution for the finished parts afterwards, or. from the original work. This service is mainly used by those customers who need a specific part or component, but do not have the original production documentation for it, or need to upgrade it. Subsequently, we also ensure the production of the component and support the required properties with measurements or provide a certificate of properties.

SHARING OF METALS

and metal components

We achieve the desired surface roughness characteristics of the finished part after CNC milling, CNC turning or hardening. The customer can also rely on us for the final finishing of the manufactured part. We can then use measurements to confirm that the parts are manufactured exactly according to the specified quality and appearance requirements.

HEAT TREATMENT

and surface treatment of metals

Depending on the production process and the specified criteria for the strength of the part, we can process metal parts by heat treatment methods such as annealing, cementing, hardening or nitriding. By heat treatment, we significantly change the properties of metals and metal surfaces to achieve the desired properties or functionality. Our services also include metal surface treatments such as blackening, chemical nickel plating and zinc plating (for steel components) or anodizing of aluminium components. Metal finishing can change the colour of the metal surface and also protect it from possible corrosion.

ELECTRICAL DISCHARGE MACHINING

metal components

Problematic and complicated shapes are machined thanks to the technology of electroerosive machining and countersinking. Thanks to this, we are able to ensure the production of more complex parts and components and thus satisfy even the most demanding requirements of our clients. Precise and detailed work is not a problem for us.

MATERIAL DELIVERIES

and material separation

Our services also include the supply and cutting of metal material, stainless steel material, bar stock and sheet metal in the quantities, thicknesses and lengths required by our clients. We can deliver the material with our own vehicle and ensure its fast but also safe transport.

PRODUCTION AND ASSEMBLY

assemblies and subassemblies

We deal with the design, manufacture and assembly of complete assemblies and sub-assemblies for various industries. These are tailor-made solutions that help our clients achieve the desired results in their production processes. We cooperate with the automotive, electrical and food industries.

MEASUREMENT PROTOCOLS

and certificates

In case you need officially confirmed measurements or protocols for a manufactured part, we can also provide you with these documents. After CNC milling or CNC turning, customers need to know whether we have met the prescribed parameters and requirements for quality, dimensions and functionality. Thanks to the measurement protocols, you have proof of our precise and high-quality work in your hands.